Bauxite - Mining & Drilling :

It is usually strip mined (Surface Mining) because it is almost always found near the surface of the terrain, with little or no overburden. Developmental drilling entails demarcation of the mining area by drilling cores and then defining the position of the ore body. Samples of the bauxite are collected from a series of holes drilled by an air-core drilling rig to an average depth of 3.5 meters, 75 meters apart in a grid formation. The samples are analysed for the amount of alumina, silica, and iron oxide to delineate the extraction zones.

Blasting :

Blasting or ripping off some parts of the ore that cannot be dug easily. This involves drilling and placing explosives, or ripping with large bulldozers. Blasting is an essential part of the Mining Cycle. In virtually all forms of mining, rock is broken by Drilling and Blasting the rock. Blasting technology is the process of fracturing material by the use of a calculated amount of explosive so that a predetermined volume of material is broken.

Excavation :

This Excavation process is carried out systematically through drilling, blasting and mucking, under the guidance and supervision of our well Qualified Engineers, Govt. approved Blaster and Geologist. Excavator and dumpers remove the blasted and loosened material.

Sizing & Sorting of Bauxite :

Once the Excavation process is done, Bauxite is sent for the Sizing and Sorting process, where Sorted Bauxite is graded by their Quality (Chemical Compositions) namely High Grade ( Al2O3 > 54-58%), Medium Grade ( Al2O3 > 50-54%) & Low Grade ( Al2O3 > 50%).

High-Grade Bauxite :

Only High-Grade Bauxite is used in the process of Calcination of Bauxite. To do so, High-Grade Bauxite is transported from Mine to Calcination Plant for further calcination process.

Jaw Crusher :

Jaw Crusher is used to crush bauxite ore into small particles. In this process, Large Raw Bauxite Ores are fed to the Jaw Crusher evenly and gradually through the Hopper for primary crushing. the material is then transferred to feed in Silo by belt Conveyors and Elevators.

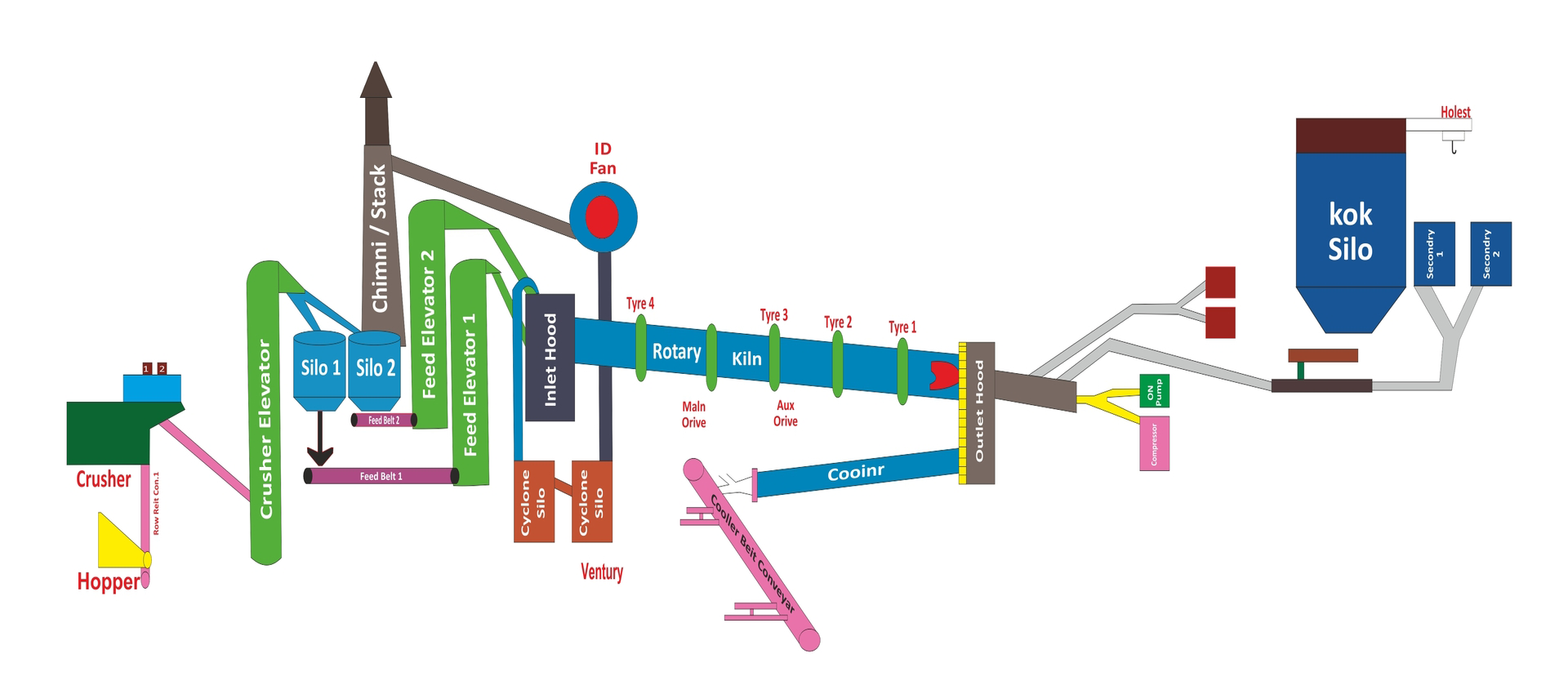

Rotary Kiln :

In this Stage, Bauxite is fed to the Rotary Kiln from Silo through the elevators and conveyors. A rotary kiln is a pyro-processing device used to raise materials to a high temperature (calcination) in a continuous process. The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. Bauxite, which is to be processed is fed into the upper end of the cylinder. As the kiln rotates, Bauxite gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. A very high temperature from 850 °C to 1600 °C continuously flows in the kiln. The fuel for this may be Gas, Oil, Pulverized Petroleum Coke or Pulverized Coal.

Cooling Outlets :

Once the Calcination process is complete in Kiln, Heated Bauxite is carried out from Kiln to the Cooler automatically, where it is cooled to a Normal temperature and the material that can meet standards will be carried away for the Crushing and Grinding.

Crushing and Grinding :

The material that comes out from the Cooler is usually a size of between 0 to 40 mm, which is crushed into the size of 0 to 10 mm by Jaw Crusher in the Crushing Process. In the Grinding Process, Material is then crushed in different sizes as per the customer's requirement such as 0-1, 1-3, 3-5 mm (by Roll Crusher) and 100 mesh, 120 mesh (by Ball Mill).

Testing :

Laxmiratna has its own Chemical Testing Laboratory along with the Calcination Plant. The laboratory is well equipped and staffed to undertake a conventional wet chemical analysis as well as for rapid instrumental determinations of various elements in Raw Bauxite and Calcined Bauxite.

Product Arangement :

Once the testing is done, Size & Quality wise Calcined Bauxite such as Low Ferric, Semi Low Ferric, General Grade, Super General Grade are stored in Warehouse.

Packaging & Transportation :

In this last stage of a process, Bauxite is packed in different size of Bags on Buyer's Preferences such as Loose in Bulk, 50kg New PP Bags & 1 MT Jumbo Bags. and then it is transported to the Buyers’ stated location.